Has your site been relying on “tried and true” spill containment units that fail to get the job done? While traditional systems, like shale bins and poly liners, have been used consistently for wash water containment for many years, they have some crucial flaws that make them dangerous for the environment, safety of your workers, and your site’s overall operation. In this guide, we’ll explain why shale bins and liner/tarps are outdated spill containment solutions that pose significant safety risks. Then, we’ll outline why portable wash pads are a better choice for all your equipment washing needs. Keep reading to learn more!

Traditional Containment Methods

Shale bins and liners/tarps are often used as spill containment systems when washing equipment on industrial sites. However, both systems present significant issues.

Shale Bins

Shale bins, while sturdy, are not engineered specifically for equipment washing. These heavy-duty industrial containers present problems, including:

- Restricted working space, making it difficult to maneuver around equipment.

- They are primarily designed for solid waste, not wash water containment, meaning that drainage is often problematic.

- The worker walks through all the contaminants as there is no raised floor

- Their fixed dimensions limit access to larger equipment, creating logistical challenges.

- Integration with water treatment systems is difficult at best.

- The workflow isn’t optimized for efficient equipment washing procedures.

Tarps & Poly Liners

Tarps/liners represent the most basic approach to containment but deliver the least reliable performance. Why risk environmental compliance with such a vulnerable solution? Even heavy-duty tarps present significant drawbacks:

- They tear easily under equipment weight, especially with heavy-duty equipment

- Creating effective seals at edges and seams proves nearly impossible

- Their short lifespan requires frequent replacement, increasing long-term costs

- Environmental risks remain high due to potential containment failures

Even with careful handling, tarps cannot withstand the demands of industrial equipment washing over time.

Key Advantages of Portable Wash Pads

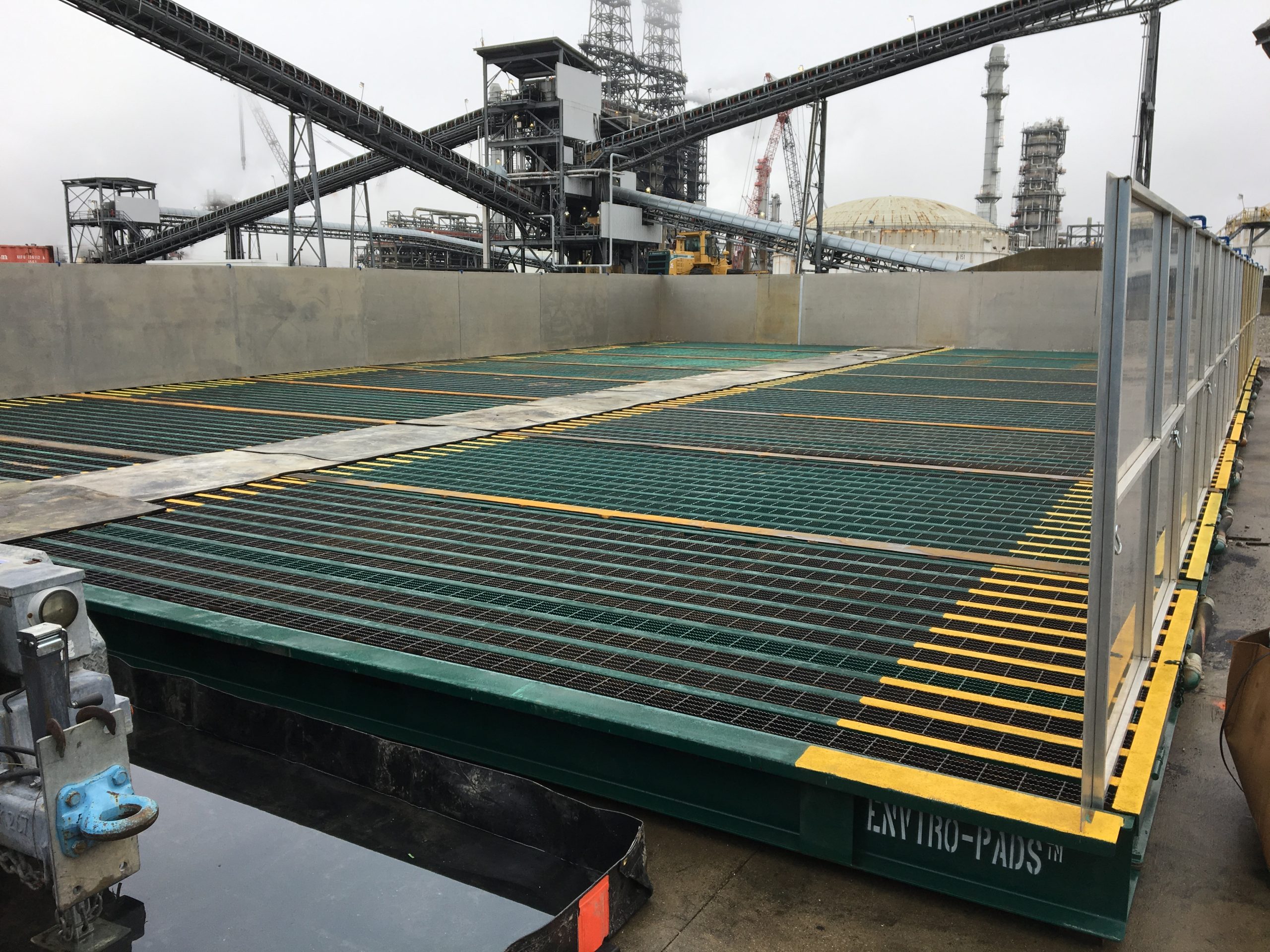

Now that we’ve identified the risks of traditional washing methods let’s discuss how enviro-pads portable wash pads can make your operation safer, more environmentally compliant, and more efficient.

1. Increased Safety and Better Working Conditions

One of the most significant benefits of a properly designed wash pad is effective drainage. Unlike shale bins and tarps, high-quality portable wash pads incorporate grating surface and channels that divert water away from the working surface. This smart design has multiple benefits, including:

- Dramatically reducing slip and fall hazards in the work area.

- Minimizing exposure to contaminated and potentially harmful wash water.

- Reducing worker fatigue through improved conditions.

Also, traditional washing systems typically submerge hoses and washing equipment in accumulated wash water. When you use a portable wash pad, everything stays dry, which improves operational efficiency and extends equipment lifespan over time.

2. Customization Options for Operational Efficiency

Industrial operations have unique equipment types, washing requirements, and environmental conditions. What makes portable wash pad systems truly valuable is their adaptability to specific operational needs.

The customization capabilities extend far beyond basic dimensions:

- Modular components that can be configured in multiple arrangements

- Customizable access points and dividers for large or unique equipment

- Integration with specialized features for cold weather operations

This flexibility allows operations to develop containment solutions that address their specific challenges while optimizing workflow efficiency. Unlike one-size-fits-all approaches with tarps or repurposed shale bins, engineered wash pad systemsadapt to your operational needs rather than forcing operations to adapt to containment limitations.

3. 100% Guaranteed Containment

Proper spill containment is more important now than ever, especially due to increasingly strict environmental regulations. Unlike unreliable and flawed traditional washing systems, Enviro-Pads portable wash pads offer equipment wash containment that you can count on. Don’t risk environmental contamination–opt for a portable wash pad specifically engineered for the harsh demands of industrial equipment washing.

These systems are built for long-term performance, with models lasting 20+ years, even under the most demanding industrial conditions. Unlike temporary solutions, our wash pad systems represent a proper investment in your operation’s efficiency and environmental compliance.

Get a Quote for Your Portable Wash Pad Today!

Ready to stop relying on outdated spill containment solutions that risk the safety of both your workers and the environment? When you partner with Enviro-Pads, you can rest assured that you are investing in a system that delivers every single time. With over 40 years of industry experience, our team has built custom containment systems for companies across Canada, United States of America and Overseas. Contact us to start building your custom portable wash pad today!

THE SOLUTIONS FOR YOUR SOLUTIONS

Primary and Secondary Containment

Made in Canada For All Seasons

THE SOLUTIONS FOR YOUR SOLUTIONS

Primary and Secondary Containment

Made in Canada For All Seasons